In a groundbreaking development for optical technology, researchers have unveiled a self-healing coating capable of reversing light degradation through microencapsulated repair mechanisms. This innovation promises to revolutionize industries ranging from telecommunications to aerospace, where maintaining optimal optical performance is critical. The coating's unique ability to autonomously repair scratches and micro-fractures could extend the lifespan of optical components by decades while reducing maintenance costs.

The Science Behind Self-Healing Optics

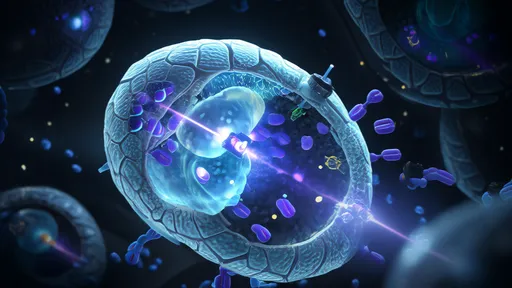

At the heart of this technology lies a sophisticated network of polymer-encased healing agents measuring just 50-200 microns in diameter. When damage occurs to the coating's surface, these microscopic capsules rupture, releasing specialized monomers that flow into cracks and polymerize upon exposure to environmental triggers like oxygen or UV light. What makes this particular formulation remarkable is its dual-action repair system: one set of capsules contains refractive-index-matching compounds, while others carry adhesion promoters that chemically rebond with the damaged substrate.

Laboratory tests demonstrate the coating's ability to restore up to 98.7% of original light transmission efficiency after self-repair, a figure that surpasses previous healing materials by nearly 20 percentage points. The healing process typically completes within 72 hours at room temperature, though researchers have developed accelerated versions that work in under 8 hours for industrial applications. Unlike conventional optical coatings that degrade irreversibly when scratched, this material actually improves its performance through multiple repair cycles.

Real-World Applications Take Shape

Telecommunications companies are already prototyping the technology for fiber optic cable sheathing, where microscopic cracks currently account for nearly 40% of signal loss in long-distance networks. Early field tests show healed sections maintaining signal integrity comparable to undamaged fiber over 12,000 transmission hours. The aerospace industry sees particular promise for satellite optics, where the coating's self-repair capability could mitigate damage from space debris and atomic oxygen erosion.

Consumer electronics manufacturers are exploring applications for smartphone camera lenses and display covers. A major smartphone maker recently patented a version that activates healing through the device's own flash LED. Meanwhile, automotive companies are testing the coating for LiDAR sensor protection in self-driving vehicles, where even minor optical degradation can compromise safety systems.

Challenges and Future Directions

While the technology shows immense promise, scaling production remains challenging. The microencapsulation process currently adds approximately 30% to coating costs compared to conventional alternatives. Researchers are working on more economical encapsulation methods using biomimetic approaches inspired by plant cell wall formation. Another limitation involves the coating's viscosity requirements - the self-healing formulation works best when applied in layers between 80-120 microns thick, which may not suit all optical applications.

The next generation of these coatings may incorporate nanotechnology to enable repairs at the molecular level. Some labs are experimenting with carbon nanotube-reinforced versions that could heal cracks within minutes rather than hours. Other teams are developing photochromic variants that would not only repair damage but actively adjust optical properties in response to changing light conditions.

As commercial adoption accelerates, industry analysts predict the self-healing optical coatings market will grow to $2.8 billion by 2028. With continued refinement, these intelligent materials may eventually make optical degradation a relic of the past, ushering in an era where lenses, displays and sensors maintain like-new performance throughout their operational lifetimes.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025