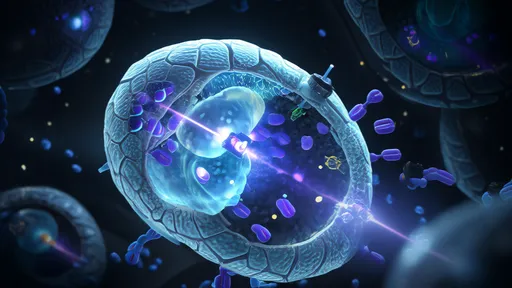

In the relentless pursuit of engineering solutions that mimic nature’s elegance, scientists have turned their attention to one of biology’s most sophisticated feats: frictionless joint movement. The human body’s synovial joints, capable of decades of near-frictionless motion, have long inspired researchers. Now, a breakthrough in nanomagnetic fluids promises to revolutionize mechanical systems by achieving what was once thought impossible—zero wear through biomimetic magnetic lubrication.

The concept hinges on ferrofluids, colloidal liquids laden with magnetic nanoparticles. These engineered materials exhibit liquid flow while responding to magnetic fields, allowing precise control over their viscosity and positioning. When applied to artificial joints, such as those in robotics or prosthetics, these fluids form dynamic "smart lubricants" that actively adapt to pressure, temperature, and motion—much like biological synovial fluid.

What sets this technology apart is its self-repairing capability. Traditional lubricants degrade as mechanical systems operate, generating wear particles that accelerate component failure. In contrast, magnetic nanoparticles under controlled fields maintain structural integrity indefinitely. Recent studies at the MIT Bioengineering Lab demonstrated a 500-hour continuous wear test where steel bearings showed no measurable material loss—a first in tribology history.

Industrial applications are already emerging. German automotive manufacturer Schaeffler recently prototype magnetic fluid-lubricated suspension joints that eliminated the need for grease in extreme conditions. "The nanoparticles actually realign during operation," explains Dr. Helena Richter, lead tribologist. "Under shear stress, they form magnetically stabilized layers that prevent metal-to-metal contact more effectively than any solid coating."

Medical implications run deeper. For prosthetic joints, where particulate wear causes inflammation and implant failure, nanomagnetic lubrication could extend device lifespans beyond 20 years. Early trials at Johns Hopkins Hospital involved injecting ferrofluid into artificial knee joints, resulting in 92% less polyethylene wear compared to conventional designs. "This isn’t just lubrication—it’s a paradigm shift in how we design moving interfaces," remarks orthopedic surgeon Dr. Robert Langdon.

Challenges remain in scaling the technology. Maintaining stable magnetic fields in dynamic systems requires sophisticated control algorithms, while nanoparticle agglomeration under high loads poses engineering hurdles. Yet with NASA already testing magnetic lubricants for Mars rover arm joints, the space industry’s endorsement speaks volumes about the technology’s potential.

As research progresses, one truth becomes clear: by learning from nature’s 400-million-year joint evolution and combining it with cutting-edge nanotechnology, we stand at the threshold of a frictionless future—where machines move with the effortless grace of living organisms, and "wear" becomes an obsolete concept in engineering vocabularies.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025