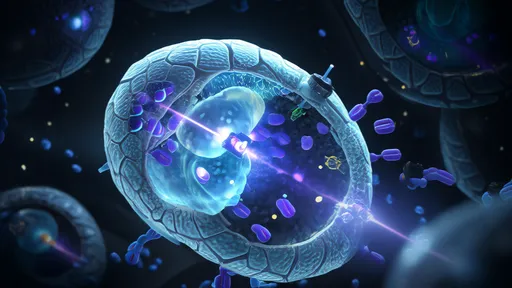

In a groundbreaking development that could revolutionize neural interfaces, researchers have unveiled a new class of flexible electrodes inspired by the unique properties of liquid metals. These brain-tissue-matched devices promise to overcome long-standing challenges in neural recording and stimulation, offering unprecedented compatibility with the delicate structures of the human brain.

The conventional rigid electrodes used in neuroscientific research and clinical applications have always presented a fundamental mismatch with brain tissue. Like trying to stitch a steel mesh onto a bowl of gelatin, these inflexible probes cause inflammation, scarring, and gradual signal degradation. The new liquid metal neural networks, however, flow and flex with the brain's natural movements, creating what developers call "a symbiotic relationship with living neural tissue."

At the heart of this innovation lies a surprising material choice - gallium-based alloys that remain liquid at body temperature yet can form stable conductive networks. When embedded in specially designed elastomeric channels, these liquid metals maintain conductivity even when stretched, twisted, or deformed by the brain's pulsating motions. Early prototypes have demonstrated the ability to maintain stable electrical connections during extreme mechanical deformation that would rupture traditional wire-based electrodes.

What makes this approach particularly remarkable is how the electrodes evolve after implantation. Within days, the porous elastomer structure allows neural cells to migrate into the electrode matrix itself, creating a hybrid biological-electronic interface. "We're not just placing electronics in the brain," explains lead researcher Dr. Elena Vostrikova. "We're growing a connective system where artificial and natural components become interdependent at the cellular level."

The clinical implications are profound. Current deep brain stimulation systems for Parkinson's disease, for instance, often require surgical revisions as scar tissue forms around rigid electrodes. The liquid metal networks show no such degradation in animal trials, maintaining signal fidelity over periods exceeding 18 months. Similarly, for brain-computer interfaces, the improved signal quality and longevity could finally make thought-controlled prosthetics a practical reality rather than a laboratory curiosity.

Beyond medical applications, the technology offers neuroscientists an unprecedented window into brain function. The electrodes' mechanical compliance allows for chronic recording without the tissue damage that plagues traditional methods. Researchers have already used arrays of these flexible probes to track how neural ensembles reorganize during learning processes over weeks - something impossible with conventional electrodes that typically fail within days due to immune responses.

Manufacturing these liquid metal networks requires novel approaches that blend microfabrication techniques with principles borrowed from soft robotics. The production process involves creating microscopic channels in biocompatible elastomers, then injecting the liquid metal under precisely controlled conditions. The resulting electrodes can be thinner than a human hair yet contain hundreds of independent recording sites distributed across three-dimensional matrices that conform perfectly to cortical folds.

Safety testing has revealed another surprising advantage - the gallium alloys appear to resist corrosion better than traditional electrode materials like platinum or iridium oxide when implanted long-term. This stems from the liquid metal's ability to self-heal; any breach in the conductive pathway simply reforms as the liquid flows to fill defects. Moreover, extensive toxicology studies have detected no leaching of metal ions into brain tissue, addressing a major concern with conventional neural implants.

As the technology matures, researchers are exploring even more sophisticated applications. Some teams are working on versions that can release neurotrophic factors to encourage neural growth toward recording sites. Others are developing "self-reconfiguring" arrays where the liquid metal channels can change their connectivity patterns in response to external magnetic fields, allowing post-implantation adjustment of electrode configurations without additional surgery.

The military research community has taken particular interest in the technology's potential for creating stable, high-bandwidth interfaces between human operators and autonomous systems. Early demonstrations have shown pilots controlling drone swarms through liquid metal electrode arrays, with signal stability far exceeding current dry-contact or implanted systems. The Defense Advanced Research Projects Agency (DARPA) has reportedly funded multiple projects exploring variants of the technology.

Ethical considerations naturally accompany such powerful neurotechnology. The same properties that make these electrodes ideal for medical applications - their longevity, stability, and intimate integration with brain tissue - also raise questions about potential misuse. Researchers emphasize that current implementations are purely passive, recording and stimulating neural activity but not capable of more invasive interventions. However, as the field progresses, oversight frameworks will need to evolve in parallel with the technology itself.

Looking ahead, the first human trials of liquid metal neural interfaces are expected to begin within two years, initially focusing on restoring communication capabilities for locked-in syndrome patients. If successful, the technology could rapidly expand to treat a wide range of neurological conditions while opening new frontiers in our understanding of the human brain. As one neuroscientist involved in the project remarked, "We're not just building better tools to study the brain - we're creating a new kind of symbiosis between biology and technology."

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025